The issue of embedded Multimedia cards versus Solid State Drive (eMMC vs SSD) can be a consideration for PC or laptop storage, the designers of embedded systems requiring the storage of relatively large volumes of (local) data may be pondering the issue too. Both are solid state technologies. But which would you use, where and why?

eMMC

To set the scene, let’s first talk about MMC. It was developed in 1997 as a compact removable storage solution for use in digital cameras, mobile phones and PDAs. However, with the creation of the Secure Digital Music Initiative (SDMI), intended to help combat music piracy, the Secure Digital (SD) format was developed in 1999 to be compatible with digital rights management.

This and certain form factor advantages SD has over MMC, led to the latter’s fall from popularity. While cards are still available, few products are designed with MMC slots these days. However, the underlying technology lives on in an embedded variant called e.MMC.

The Joint Electron Device Engineering Council (JEDEC) describes e.MMC as…

“…an embedded non-volatile memory system, comprised of both flash memory and a flash memory controller, which simplifies the application interface design and frees the host processor from low-level flash memory management.”

… noting that the official name for the memory type has a dot between the e and the first M. For convenience, we’ll stick with eMMC for the remainder of this blog, though. The latest electrical standard for eMMC is 5.1, which was published by JEDEC in January 2019 as JESD84-B51A.

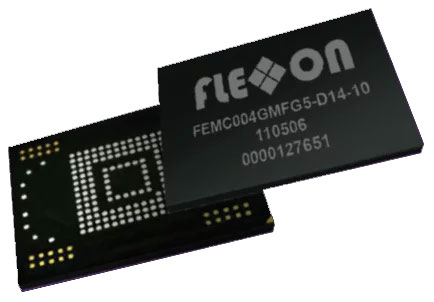

Rather than a card, e.MMC is in IC/chip form factor. It is typically soldered to a product’s PCB; sometimes as a packaged chip and sometimes as bare die.

Above, an example of an eMMC chip. It is a Flexxon device with 100 ball BGA device for surface mounting onto a PCB.

Above, an example of an eMMC chip. It is a Flexxon device with 100 ball BGA device for surface mounting onto a PCB.

In terms of capacities, eMMC chips typically range from a few to few hundred GB. For example, Flexxon’s AXO series goes up to 512GB, thanks to the OEMs use of 3D TLC (see the 3D NAND section of our ‘What is NAND memory guide). However, most applications (certainly embedded systems) can be served by just a few GB, as data can also be stored in the cloud. And some computing platforms will feature both eMMC and SSD.

SSD

For this technology, memory capacity tends to be greater than that of eMMC; at typically 128GB to a few terabytes (TB). However, when considering eMMC vs SSD it’s not just about capacity. These factors come in to play too:

- SSD is much faster. 5.1-compliant eMMC will perform sequential reads at 250MB/s and sequential writes at 125MB/s – but an SSD with a SATA III interface will deliver read/writes at 500MB/s. As for NVMe, it’s even faster. For example, the Samsung 990 Pro (which is in an M.2 format) that launched in October 2022 has read speeds of up to 7,450MB/s and write speeds of up to 6,900MB/s.

- SSDs generally have better memory wear levelling.

But these benefits are not enough to displace eMMC in all instances. SSD is more expensive, so eMMC is often used in budget laptops and PCs, for example.

So, eMMC vs SSD? It depends on your application. If you are building a high-performance computer for an industrial application, or an embedded system that requires high-performance high-capacity memory then SSD is the way to go. Alternatively, if you are after a storage capacity of up to just a few GB, and you have tight budget, eMMC makes sense.

Flexxon eMMC is used in many industrial applications including the automotive sector. Flexxon’s automotive-grade eMMC is widely used in automotive applications, navigation and vehicle infotainment applications such as 3D maps drive recorder, satellite radio, autonomous drive OS and Apps, telemetric and traffic monitoring. This eMMC works perfectly in harsh environments. It makes sure the application performs better within the upgraded technical support, extended life, and stable roadmaps.

Whichever technology you opt for we recommend you benchmark products, as not all eMMCs or SSDs are equal. Also, within reason, go for a higher capacity than you need – particularly for eMMC as it has the lower performance wear-levelling capability.