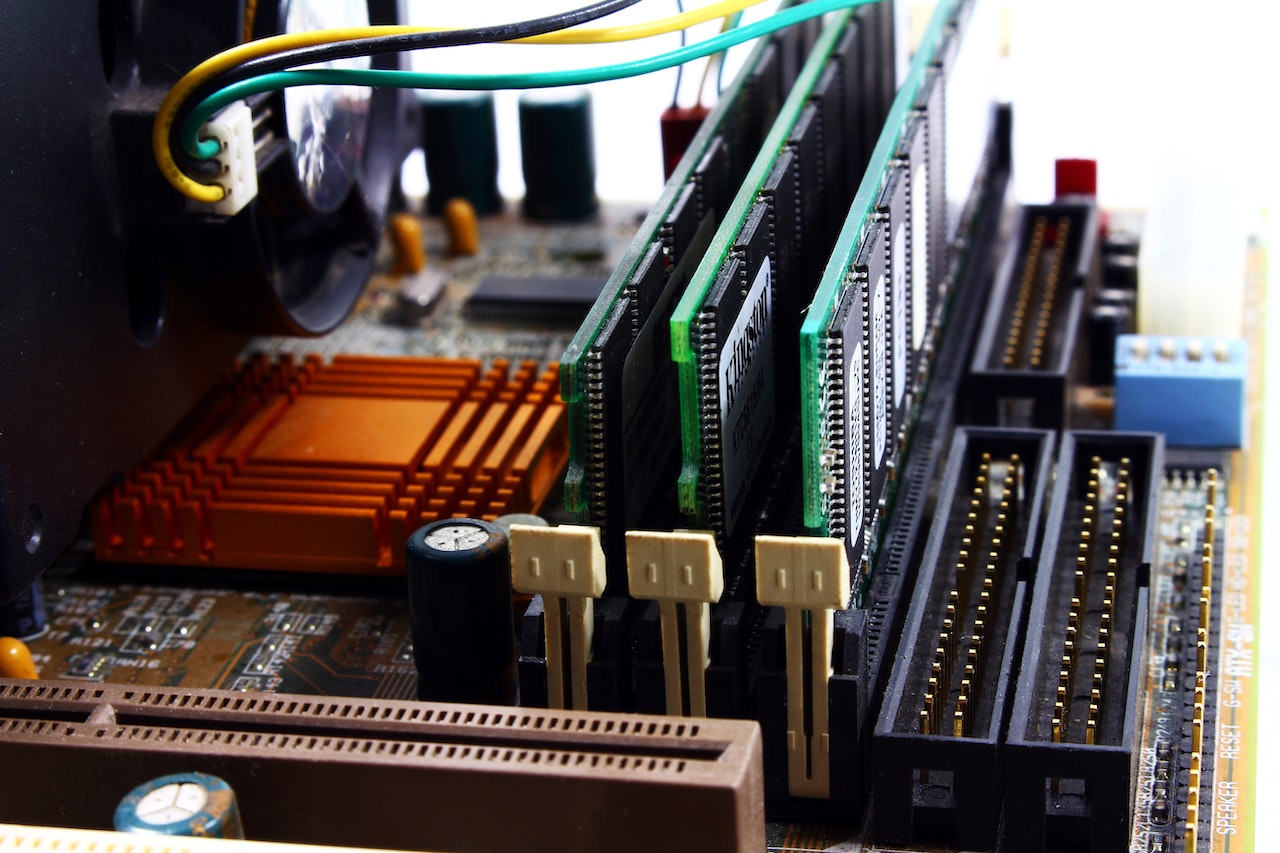

In an increasingly digitalised world, businesses are relying on efficient memory products to streamline their operations and improve their overall performance. With the increasing demand for customised solutions tailored to different industries, it is crucial for businesses to select and customise memory products that best suit their unique needs and requirements. This is especially true when it comes to industrial memory solutions designed for customers who need more than standard commercial memory to achieve optimal performance. In this comprehensive guide, we will explore the various factors to consider when selecting industrial memory products, taking a deep dive into the customisation options, and showcasing how these tailored solutions can significantly enhance your application’s efficiency and reliability.

Nexus specialises in memory products tailored to customers searching for more advanced solutions than standard commercial memory. When choosing an industrial memory product, there are numerous factors to evaluate, such as the specific memory technology, desired performance levels, environmental requirements, and device compatibility. Additionally, it is essential to understand the comprehensive range of customisation options available to ensure that your memory product selection meets and exceeds your application’s most exacting demands.

The following guide aims to provide a thorough exploration of the different memory technologies, their attributes, and their respective applications across various industries. Furthermore, we will delve into the critical aspects of memory product customisation, enabling you to make informed decisions when selecting and tailoring memory solutions. By understanding the intricacies of industrial memory products, you can navigate through the complexities of the digital landscape with efficiency and proficiency, maximising your business performance in the most demanding applications and scenarios. Keep reading to discover how the right industrial memory product selection and customisation can transform your business operations and unlock your potential for success in the modern age.

Exploring Different Memory Technologies

An essential step towards choosing the right industrial memory product is understanding the various memory technologies available. These memory technologies offer different features, performance levels and applicable scenarios:

- DRAM (Dynamic Random Access Memory): DRAM is a volatile memory technology that requires continuous power to retain data. It is commonly used due to its high data transfer rates, low latency, and capacity for large memory densities. DRAM is ideal for use in applications that require high-speed data processing, such as workstations, servers, and high-performance computing.

- SRAM (Static Random Access Memory): SRAM offers faster access times and lower power consumption than DRAM; however, it tends to have smaller storage capacities and higher cost per bit. SRAM is suitable for applications where speed and low power usage are critical, such as cache modules, real-time systems, and high-speed memory buffers.

- NAND Flash: NAND Flash is a non-volatile memory technology that retains data even when power is lost. It provides high-density storage options, fast read speeds, and low power consumption. NAND Flash is an ideal solution for applications where robust data retention and high storage capacities are essential, such as solid-state drives (SSDs), USB drives, and memory cards.

- NOR Flash: NOR Flash is another non-volatile memory technology that offers fast read and write speeds and robust data retention capabilities. However, NOR Flash generally has lower storage capacities and higher costs compared to NAND Flash. It is commonly used in embedded systems, firmware storage, and BIOS applications.

Performance Characteristics and Environmental Requirements

When evaluating industrial memory products, it is crucial to consider their performance characteristics and environmental requirements. Key factors to examine include:

- Speed: Evaluate the desired data transfer rates, access times, and bandwidth capacities suitable for your specific application.

- Capacity: Determine the optimal storage capacities required to accommodate your application’s data storage and processing needs.

- Operating Temperature: Assess the temperature ranges within which your memory product needs to function reliably. Industrial memory solutions often cater to wider operating temperature ranges compared to standard commercial memory.

- Resistance to Shock, Vibration, and Humidity: Ensure that the memory product you choose can withstand the environmental conditions typically encountered in your application and industry, such as vibrations, shocks, and humidity.

Customisation Options for Industrial Memory Products

To better suit your unique application needs, industrial memory products offer various customisation options. Some of these options include:

- Form Factor: Opt for the most appropriate form factor for your memory product based on the space constraints and layout of your system. Common form factors include DIMM, SODIMM, UDIMM, and custom PCB designs.

- Memory Interface: Choose the most suitable memory interface for your application, considering factors such as speed, compatibility, and power usage. Common memory interfaces include DDR4, DDR3, and DDR2.

- Special Features: Some industrial memory products offer unique features for enhanced performance and reliability, such as error-correcting code (ECC) support, wide temperature operation, and ruggedised designs.

- Firmware Customisation: Tailored firmware optimisations can improve product compatibility, enhance security features, or modify power-saving modes to better suit your application requirements.

Ensuring Device Compatibility and Integration

The final step in selecting an industrial memory product is ensuring seamless device compatibility and integration:

- Hardware Compatibility: Ensure that the chosen memory product is compatible with your existing system hardware, including processors, motherboards, and peripheral devices.

- Software Compatibility: Verify that the memory product supports your application’s software, operating systems, and drivers.

- Integration Support: Work with an experienced industrial memory provider who can offer technical support and assist with your product’s integration into your existing systems.

Conclusion

Selecting and customising industrial memory products is a crucial task that can greatly influence your application’s efficiency, performance, and reliability. By understanding the various memory technologies, evaluating performance characteristics and environmental requirements, exploring customisation options, and ensuring device compatibility, you can make informed decisions that lead to success in today’s dynamic and competitive business landscape. Trust Nexus to provide expert guidance during the selection and customisation process, ensuring that your chosen memory solution meets and exceeds your unique requirements. With the right industrial memory product in place, your business can achieve optimal performance and reliability, enabling continued growth and prosperity in the digital age.